Miner Parts Procurement & Maintenance Guidelines

Recommendations from the Repair Team

This document is based on our long-term, hands-on experience in miner repair and maintenance. It is intended to help site owners and miner owners make informed decisions when purchasing parts and arranging repairs, with the goal of reducing downtime, repeat failures, and long-term operating costs.

1. Our Scope of Work

- Hashboard repair

- Power supply (PSU) repair

- Cleaning, maintenance, and refurbishment of heavily contaminated, dust-laden, or oil-exposed miners

- Stability-focused servicing for miners operating in high-temperature, high-load, 24/7 environments

We regularly handle machines that others consider “unrepairable” or “scrap,” which gives us direct insight into how component quality affects long-term reliability.

2. Parts Procurement Recommendations

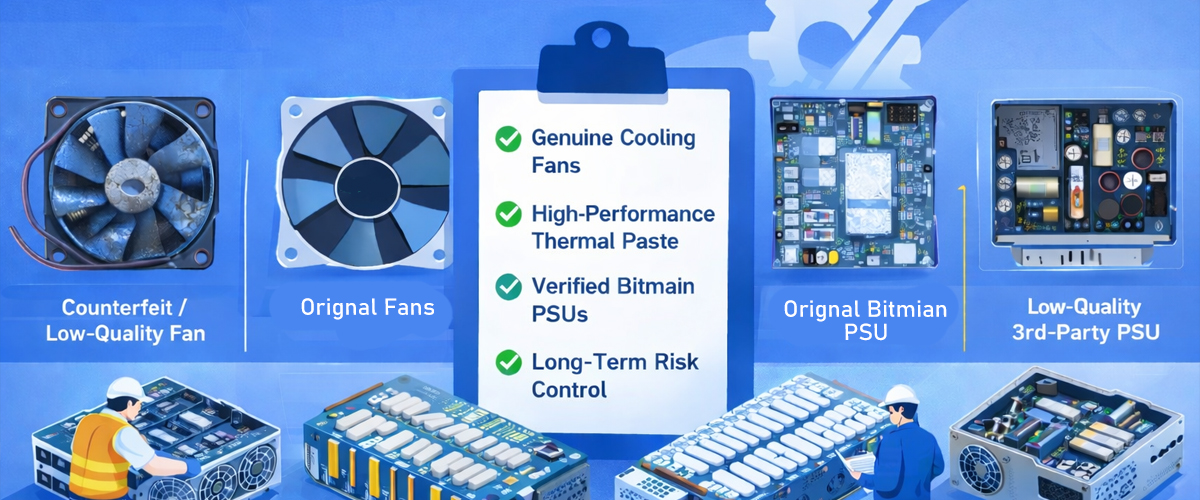

2.1 Cooling Fans

We strongly recommend using genuine Bitmain fans or fans with fully traceable sources that meet original specifications.

From extensive repair experience, many third-party fans on the market match original specifications on paper. Some even carry printed logos that closely resemble original manufacturers.

However, in continuous high-temperature and high-dust mining environments, these fans frequently show premature bearing failure, RPM degradation, abnormal noise, and shortened service life.

Although lower-cost fans may appear economical at purchase, the true cost often increases due to repeated replacements, additional labor, miner racking/unracking, downtime, and lost hash rate.

Minimum recommended standard:

- Traceable supply source

- Specifications matching original manufacturer requirements

- Clearly identified model and batch information

2.2 Thermal Paste (Thermal Interface Material)

Thermal paste quality and replacement procedures are critical to hashboard stability and lifespan.

Common issues include unclear sourcing, unreliable manufacturers, substitution of lower-grade materials, use of high-fluidity paste to speed application, and partial replacement instead of full removal and reapplication.

These practices may appear acceptable short-term, but problems typically surface during high-ambient-temperature periods.

Minimum recommended standard:

- Thermal conductivity ≥ 4 (19s Miners)-6 (21s Miners)- 8-10 W/m·K(higher Version)

- Complete removal of old thermal paste during service

- Full, uniform reapplication

- Partial or spot reapplication is not recommended

2.3 Third-Party Power Supplies (PSUs)

Using non-Bitmain PSUs can reduce initial procurement costs, but introduces higher long-term risk.

Non-Bitmain PSUs are excluded from repair and stability guarantees. Failed non-Bitmain PSUs are classified as scrap and are not repaired.

Inconsistent component quality, lack of compatible donor units, and inability to reliably guarantee service life after repair make these PSUs unsuitable for responsible long-term operation.

4. Summary

In continuous mining operations, component quality differences are amplified over time. Short-term savings on parts often result in higher costs through downtime, repeat repairs, and operational disruption.

Using reliable components and controlled maintenance processes is not an upgrade — it is the baseline for predictable, stable operation.